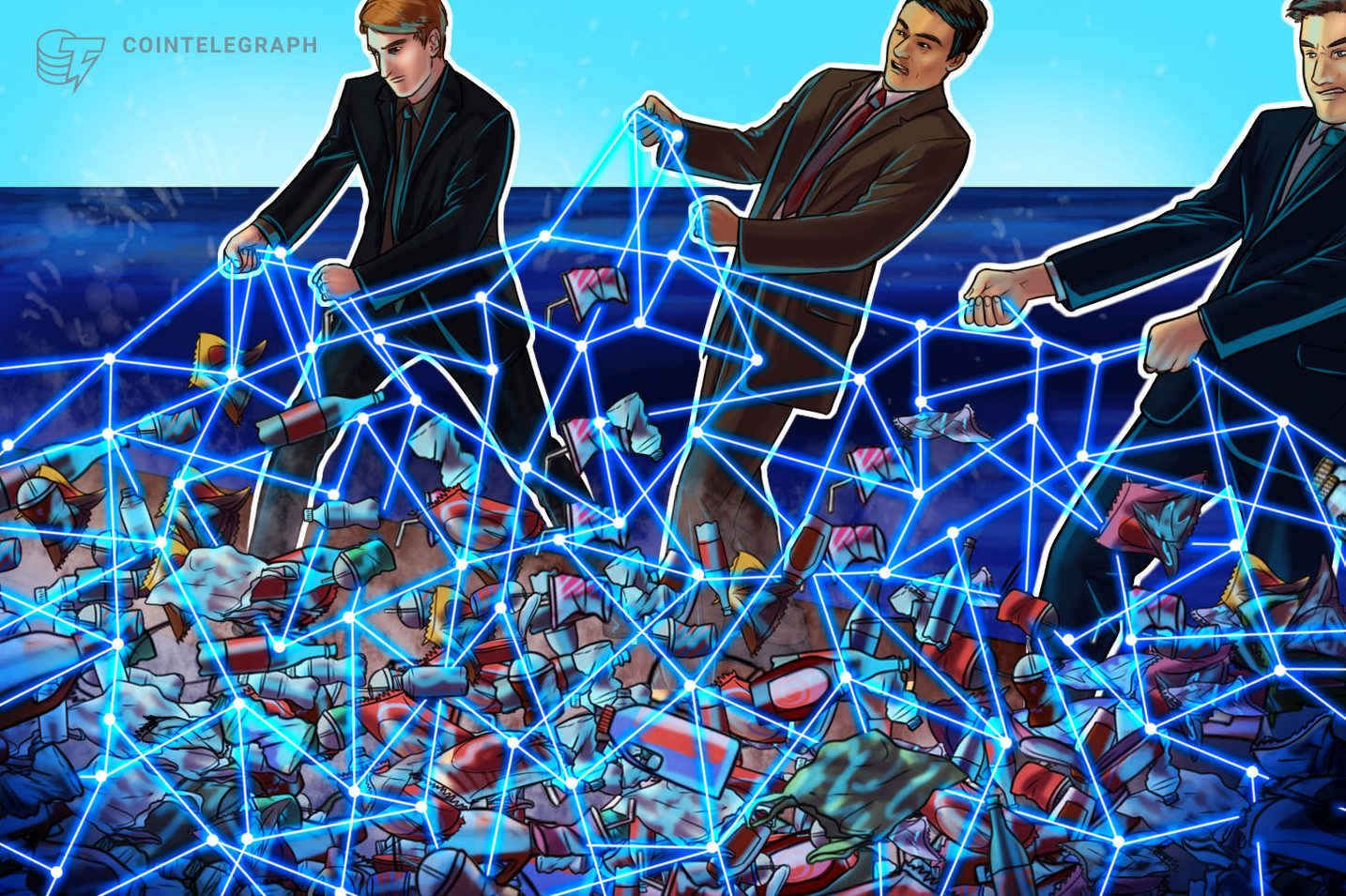

July Recycling Numbers

July numbers are in and Rundle Eco Services Ltd. continues to keep large amounts of plastic from the landfill! Each pound of plastic collected is recycled so that it can be reused for the manufacturing of new products. Thank you to all of our stakeholders, it wouldn’t be possible without you!

#recycling #plastic #yyc #entrepreneurship